-

About UsProductsCustomized SolutionProjectGalleryNews

What Architectural Wire Mesh Products Meet European Standards?

Release time: January 16, 2026Architectural wire mesh is widely used in modern European construction projects, including building façades, interior partitions, ceilings, railings, sunscreens, and safety enclosures. However, Europe is one of the most regulated construction markets in the world. To be accepted by architects, contractors, and project owners, architectural wire mesh must strictly comply with European standards related to safety, durability, sustainability, and aesthetics.

This article explains what architectural wire mesh products meet European standards, what regulations apply, and how buyers can select compliant suppliers.

1. Why European Standards Matter for Architectural Wire Mesh

European construction regulations are designed to ensure:

Structural safety

Fire resistance

Long-term durability

Environmental sustainability

Worker and public safety

For architectural wire mesh, compliance is not optional. Non-compliant products may be rejected during design approval, customs clearance, or on-site inspection.

2. Key European Standards Applicable to Architectural Wire Mesh

EN Standards (European Norms)

Architectural wire mesh products commonly fall under:

EN 10223 (steel wire and wire products)

EN 10088 (stainless steel grades)

EN 10244 (coatings for steel wire)

These standards regulate wire diameter tolerance, tensile strength, surface quality, and coating performance.

3. CE Marking Requirements

In many architectural applications, wire mesh must support CE marking, which confirms compliance with EU construction product regulations (CPR).

CE-related requirements may include:

Mechanical performance testing

Material traceability

Factory production control (FPC)

Declaration of Performance (DoP)

Architectural wire mesh used in façades, balustrades, or safety systems often requires CE conformity.

4. Fire Safety and Reaction to Fire Standards

Fire performance is critical in European architecture.

Relevant standards include:

EN 13501-1 (reaction to fire classification)

Stainless steel and aluminum architectural wire mesh typically achieve A1 or A2 fire ratings, making them suitable for public buildings such as airports, malls, and transport hubs.

5. Common Architectural Wire Mesh Products That Meet European Standards

Stainless Steel Woven Wire Mesh

Grades: AISI 304 / 316 (EN 10088 compliant)

Excellent corrosion resistance

Suitable for façades, interiors, and safety partitions

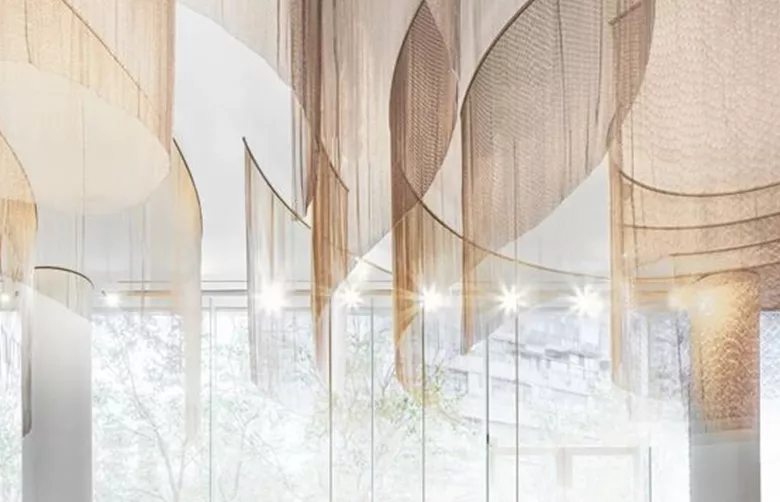

Decorative Woven Metal Fabric

Flexible architectural applications

Used in ceilings, wall cladding, and shading systems

Manufactured with precise weaving tolerance

Expanded Metal Mesh

EN-compliant steel or aluminum

Strong structural performance

Common in façades and sun-control systems

Perforated Metal Panels

Precision-punched sheets

Controlled open area and thickness

Widely accepted in European architectural design

6. Corrosion Resistance Standards for Europe

European projects often demand high corrosion resistance, especially in:

Coastal regions

Industrial zones

Outdoor façades

Accepted corrosion protection methods include:

Stainless steel (natural corrosion resistance)

Hot-dip galvanizing according to EN standards

Anodized aluminum

High-performance powder coating (Qualicoat standard)

Durability is a core evaluation factor for approval.

7. Dimensional Accuracy and Manufacturing Tolerances

European architects expect:

Precise wire diameter control

Consistent mesh opening size

Flatness and uniform appearance

Architectural wire mesh must meet strict dimensional tolerances to integrate seamlessly with curtain wall systems and architectural frameworks.

8. Environmental and Sustainability Requirements

Sustainability is increasingly important in Europe.

Architectural wire mesh products should support:

REACH compliance (chemical safety)

RoHS compliance (restricted substances)

Recyclable metal materials

Environmentally compliant products improve acceptance in green building projects and public tenders.

9. Quality Documentation Required by European Buyers

Professional European buyers often request:

Material certificates (EN 10204 3.1)

Test reports for mechanical and chemical properties

Surface treatment certifications

Factory audit records

Complete documentation significantly improves trust and approval speed.

10. Why European Projects Choose Experienced Export Manufacturers

Manufacturers supplying Europe must understand:

EU construction regulations

Project-based customization needs

Long-distance packaging standards

Stable quality consistency

Experienced Chinese architectural wire mesh manufacturers with European export history can meet these expectations efficiently.

11. Packaging and Logistics Compliance

Export packaging must:

Prevent deformation and surface damage

Protect coatings during long transit

Meet EU import handling requirements

Proper packaging ensures products arrive ready for installation without rework.

Conclusion

Architectural wire mesh products that meet European standards must comply with EN regulations, CE marking requirements, fire safety classifications, corrosion resistance expectations, and sustainability rules. Stainless steel woven mesh, decorative metal fabric, expanded metal, and perforated panels are among the most commonly accepted solutions.

For European architectural projects, selecting a compliant wire mesh product—and a knowledgeable supplier—is essential for smooth approval, long service life, and architectural success.

Recommended News