-

About UsProductsCustomized SolutionProjectGalleryNews

How to Test Woven Metal Interiors Quality Before Shipment

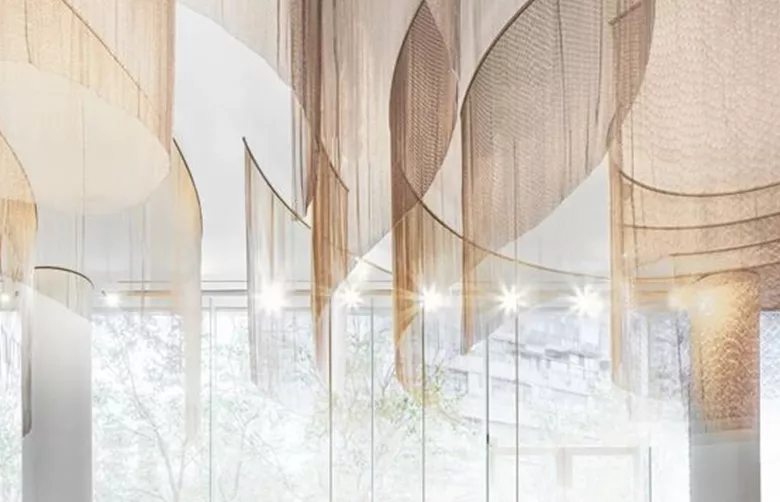

Release time: December 22, 2025Woven metal interiors, including architectural mesh panels, decorative partitions, ceiling panels, and furniture inserts, are increasingly used in commercial, residential, and public spaces due to their durability and aesthetic appeal. For international buyers, ensuring the quality of woven metal interiors before shipment is essential to avoid costly defects, delays, and disputes.

This article provides a detailed guide on pre-shipment quality testing for woven metal interiors, helping buyers verify durability, aesthetics, and compliance with project specifications.

Why Pre-Shipment Quality Testing Matters

Pre-shipment inspection (PSI) or quality testing ensures that the finished woven metal products meet both technical standards and buyer expectations. Key reasons for testing include:

Avoiding material defects such as rust, scratches, or deformation

Ensuring consistent mesh patterns and dimensions

Verifying surface treatments and coatings

Reducing risk during transportation

Meeting contractual or regulatory requirements

Testing prior to shipment provides confidence and minimizes potential losses in international trade.

1. Visual Inspection

The first step in quality testing is thorough visual inspection.

Key Points:

Mesh uniformity: Check that openings are consistent and aligned correctly

Weld quality: Ensure that joints are secure, with no loose wires or gaps

Surface finish: Look for scratches, dents, rust, or coating imperfections

Panel flatness: Verify panels are not warped or bent

Edges and borders: Ensure edges are smooth, properly trimmed, and safe for handling

Visual inspection is straightforward but essential for detecting obvious defects before more technical tests.

2. Dimensional and Tolerance Checks

Accuracy in size and shape is critical for installation.

Measure panel dimensions: Verify length, width, and thickness match the order specifications

Check mesh opening size: Confirm consistent spacing between wires

Wire diameter verification: Ensure wires are within specified tolerance

Panel alignment: For modular or frame-integrated designs, check corner angles and frame fitting

Using calipers, rulers, or laser measurement tools can provide precise dimensional verification.

3. Surface Treatment and Coating Tests

Surface treatments are crucial for aesthetics and corrosion resistance.

Common Tests:

Coating thickness test: Ensure galvanization, powder coating, or PVC coating meets project standards

Adhesion test: Check that coatings adhere well to wires without peeling

Salt spray / corrosion test: Simulate environmental conditions to detect early signs of rust

Visual color consistency: Ensure uniform color across all panels, especially for powder-coated or anodized finishes

These tests guarantee long-term durability, especially for outdoor or high-traffic installations.

4. Strength and Structural Integrity Testing

Structural performance is essential for safety and longevity.

Pull and tensile test: Check wire strength and joint security

Flexibility and deformation test: Ensure panels can withstand bending or impact without permanent damage

Load testing: For ceiling panels or partitions, simulate expected load or stress conditions

Professional testing equipment or sample load tests can identify potential structural weaknesses before shipment.

5. Sample and Batch Verification

For large orders, batch consistency testing is recommended.

Randomly select multiple panels from different production batches

Perform visual, dimensional, and coating tests on each sample

Compare results with approved sample or design specifications

Batch verification ensures that all shipped products meet consistent quality standards.

6. Packaging and Transport Inspection

Even high-quality woven metal interiors can be damaged if improperly packed.

Verify that panels are properly wrapped with protective film, cardboard, or foam

Check that bundles are securely strapped or palletized

Confirm that labels, barcodes, and batch numbers are accurate for inventory and installation tracking

Proper packing inspection prevents damage during long-distance shipping.

7. Third-Party Pre-Shipment Inspection

Many international buyers engage independent inspection agencies such as SGS, Bureau Veritas, or TUV.

Benefits include:

Objective verification of quality and compliance

Professional documentation for customs or project approval

Risk reduction for international transactions

Third-party inspections provide additional assurance for buyers sourcing woven metal interiors from China.

8. Communication with the Manufacturer

Effective communication with the manufacturer is crucial.

Share detailed inspection checklists and requirements before production

Request sample approval and photographs during manufacturing

Confirm pre-shipment inspection dates and processes

Keep records of test reports, material certificates, and production documents

Clear communication ensures that quality standards are understood and met consistently.

Conclusion

Testing the quality of woven metal interiors before shipment is essential for international buyers to ensure durability, aesthetic consistency, and compliance with project requirements. A comprehensive pre-shipment quality check should include visual inspection, dimensional verification, surface treatment tests, structural integrity assessment, batch consistency checks, packaging verification, and optionally, third-party inspection.

By partnering with a professional Chinese wire mesh manufacturer that supports pre-shipment quality testing, buyers can minimize risks, protect investment, and ensure that architectural and decorative metal interiors arrive in perfect condition for installation.

Recommended News