-

About UsProductsCustomized SolutionProjectGalleryNews

What Certifications Should Woven Metal Interiors Products Have?

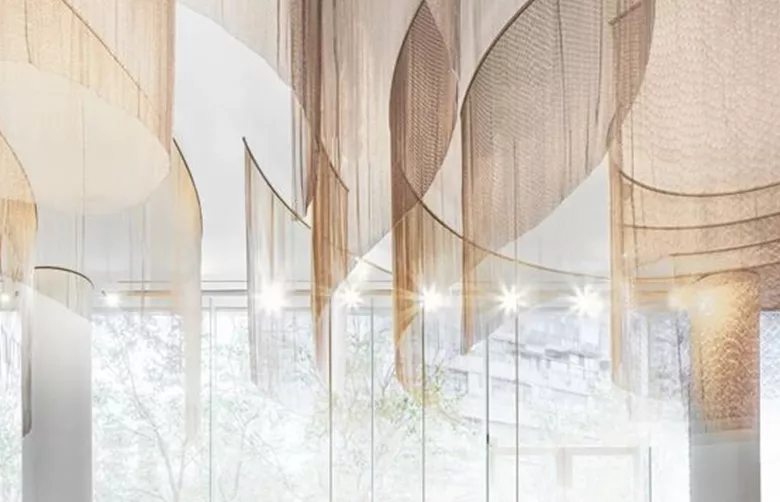

Release time: December 16, 2025Woven metal interior products are increasingly used in modern architectural and interior design projects, including wall cladding, ceilings, partitions, elevator interiors, and decorative screens. As these products are often installed in commercial, public, and high-end residential spaces, compliance with international standards and certifications is essential.

For buyers, architects, and project contractors sourcing woven metal interiors from overseas—especially from China—understanding which certifications are required helps ensure product quality, safety, and regulatory compliance. As a professional Chinese wire mesh manufacturer with a dedicated international trading platform, this article provides a comprehensive overview of the key certifications woven metal interior products should have for global markets.

1. ISO 9001 – Quality Management System Certification

ISO 9001 is one of the most important certifications for woven metal interior products.

Why it matters:

Confirms that the manufacturer follows standardized quality management procedures

Ensures consistency in raw materials, production, inspection, and delivery

Reduces risks of quality defects in large or repeat orders

For international buyers, ISO 9001-certified manufacturers are more reliable partners for long-term cooperation.

2. ISO 14001 – Environmental Management System

Sustainability is a growing concern in architectural and interior projects worldwide.

Key benefits:

Demonstrates responsible environmental practices

Confirms compliance with environmental regulations

Supports green building and sustainable project requirements

ISO 14001 certification is particularly important for projects targeting LEED or other green building standards.

3. Material Certifications (Stainless Steel & Metal Grades)

Material quality directly impacts the performance and appearance of woven metal interiors.

Common material certifications include:

Stainless steel grade certificates (SS304, SS316, SS316L)

Chemical composition analysis reports

Mechanical property test reports

These certifications verify corrosion resistance, durability, and suitability for interior applications.

4. Fire Resistance and Reaction-to-Fire Certifications

Fire safety is critical for interior architectural materials used in public buildings.

Depending on the market, woven metal interior products may require:

EN 13501-1 (Europe) fire reaction classification

ASTM E84 (USA) surface burning characteristics

Local fire safety test reports for specific countries

Metal woven products generally perform well in fire tests, but official certification is essential for project approval.

5. CE Marking (For the European Market)

For projects in the European Union, CE marking may be required depending on the application.

CE marking indicates:

Compliance with relevant EU directives and standards

Conformity in safety, health, and environmental protection

Legal eligibility for use in EU construction projects

CE compliance increases acceptance in European architectural and interior markets.

6. REACH Compliance (Chemical Safety in the EU)

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulates chemical substances used in products sold in the EU.

For woven metal interiors, REACH compliance ensures:

No harmful substances in coatings or surface treatments

Safe use in indoor environments

Compliance with EU chemical safety laws

REACH compliance is especially important for PVD-coated, painted, or powder-coated woven metal products.

7. Surface Treatment and Coating Certifications

Surface finish quality is critical for woven metal interior aesthetics.

Relevant certifications or test reports include:

Coating thickness measurement reports

Adhesion test results

Salt spray or corrosion resistance tests (where applicable)

These documents help confirm long-term durability and visual consistency.

8. Indoor Air Quality and VOC Compliance

For interior applications, indoor air quality is increasingly regulated.

Buyers may request:

Low-VOC or VOC-free coating certifications

Indoor material safety test reports

Such certifications support healthier indoor environments, especially in offices, hotels, and public buildings.

9. Project-Specific and Local Compliance Documents

Some projects or regions require additional documentation, such as:

Technical data sheets (TDS)

Installation manuals

Structural performance test reports

Local building code compliance certificates

Working with experienced manufacturers helps ensure all project-specific requirements are met efficiently.

10. Third-Party Testing and Inspection Reports

Independent verification adds confidence to certification claims.

Third-party reports may include:

Dimensional accuracy inspection

Visual quality assessment

Surface finish evaluation

Packaging and shipment inspection

These reports are especially valuable for large-scale or high-value interior projects.

Why Certifications Matter for Global Buyers

Certifications provide more than compliance—they offer:

Reduced project approval risks

Easier communication with architects and regulators

Greater trust in supplier capabilities

Long-term performance assurance

Certified woven metal interior products are more likely to be accepted in international construction and interior design projects.

Conclusion

Woven metal interior products should meet a combination of quality, safety, material, environmental, and fire performance certifications to succeed in global markets. Key certifications include:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

Material grade certifications

Fire resistance and reaction-to-fire certifications

CE marking (for EU projects)

REACH compliance

Surface treatment and coating test reports

Indoor air quality compliance

Project-specific compliance documents

Third-party inspection reports

Partnering with an experienced Chinese woven metal interiors manufacturer ensures access to certified products, customized solutions, strict quality control, and reliable international delivery. This approach helps architects, designers, and distributors confidently specify woven metal interiors that meet global standards and project expectations.

Recommended News