-

About UsProductsCustomized SolutionProjectGalleryNews

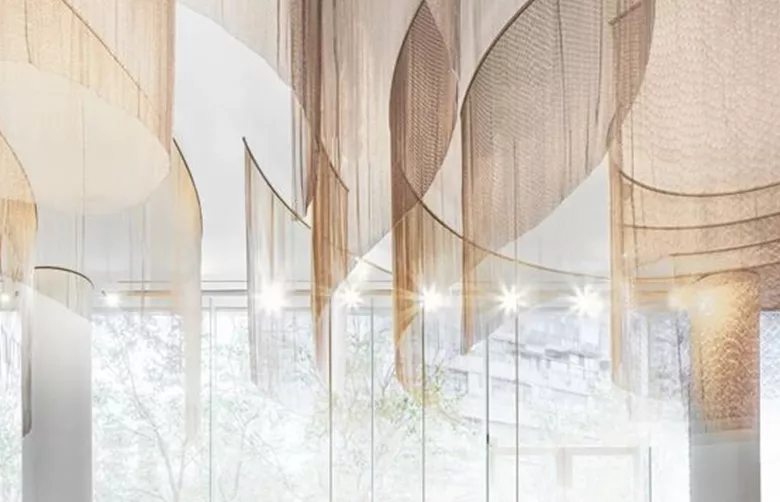

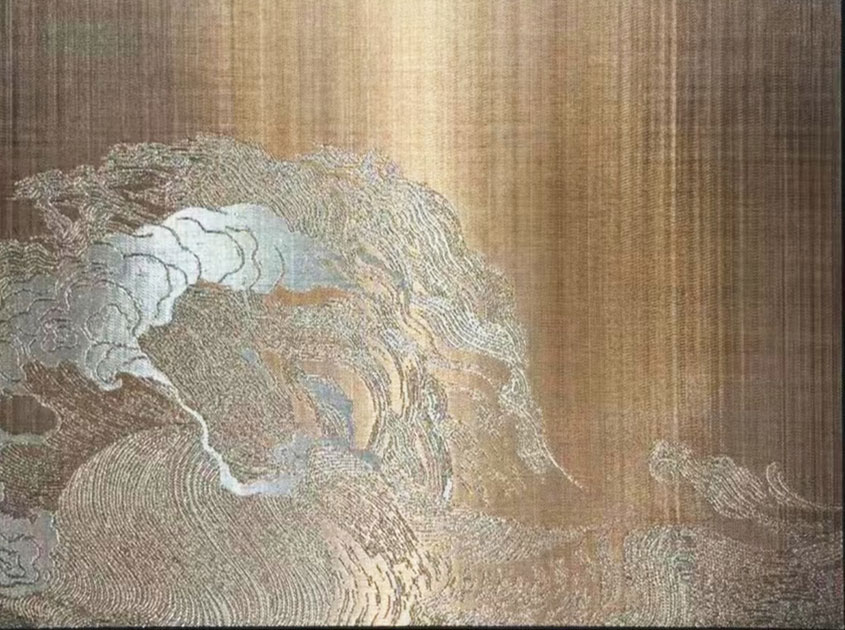

Best Architectural Woven Interiors Fabric for Construction Use in the Middle East

Release time: December 25, 2025The Middle East has become one of the world’s most influential regions for luxury construction, commercial real estate, and landmark architecture. From Dubai and Abu Dhabi to Riyadh and Doha, modern buildings increasingly use architectural woven metal fabrics to create striking interior spaces that combine beauty, performance, and durability.

This article explains which woven interiors fabrics are best suited for construction projects in the Middle East and why this material has become essential in modern Middle Eastern architecture.

Why the Middle East Prefers Woven Metal Interiors

Middle Eastern buildings face extreme climate conditions, including:

High temperatures

Intense UV radiation

Dust and sand

High humidity in coastal cities

Traditional interior materials such as wood, fabric, or plastic degrade quickly. Architectural woven metal fabric offers:

Fire resistance

Excellent ventilation

Long service life

Elegant appearance

Low maintenance

This makes it ideal for airports, hotels, malls, mosques, offices, and luxury residences.

Best Materials for Middle East Interior Mesh

1. Stainless Steel Woven Fabric (304 / 316)

Stainless steel is the top choice for high-end projects.

Benefits:

Outstanding corrosion resistance

Withstands humidity and air conditioning environments

Modern, clean metallic appearance

Easy to clean

Grade 316 is especially suitable for coastal cities like Dubai and Jeddah.

2. Aluminum Woven Metal Fabric

Aluminum offers:

Lightweight construction

Excellent resistance to corrosion

Easy installation for ceilings and partitions

Lower cost than stainless steel

It is widely used in large commercial interiors.

3. Brass & Bronze Decorative Woven Mesh

For luxury projects, brass or bronze woven fabric is popular for:

Hotel lobbies

High-end retail stores

VIP lounges

Mosques and cultural buildings

These metals provide warm golden tones that align with Middle Eastern design preferences.

Most Popular Applications in the Middle East

Architectural woven interiors fabric is widely used in:

Decorative wall cladding

Suspended ceilings

Room partitions

Elevator and stair enclosures

Hotel and mall décor

Ventilation screens

The open structure allows airflow, light control, and thermal management, essential for Middle East buildings.

Importance of Fire and Safety Compliance

Middle Eastern construction standards require:

Non-combustible materials

Fire-rated interior finishes

Structural stability

Metal woven fabric naturally meets these requirements, making it safer than textile or plastic materials.

Why Custom Design Is Critical

Middle East architects demand:

Custom weaving patterns

Specific light transmission levels

Custom colors (gold, champagne, black, bronze)

Exact panel dimensions

OEM production allows:

PVD coating

Powder coating

Anodizing

Patterned weaving

Chinese manufacturers with advanced weaving and coating technology provide this level of customization at competitive cost.

Why the Middle East Sources from China

Middle East developers increasingly source woven interiors fabric from China because:

China offers large-scale production

Advanced metal weaving technology

Competitive pricing

Shorter lead times

International project experience

Chinese architectural mesh now meets European and Middle Eastern quality standards, making it a preferred supply base.

Conclusion

The best architectural woven interiors fabric for construction use in the Middle East includes:

Stainless steel woven mesh

Aluminum woven metal fabric

Brass and bronze decorative mesh

Custom-colored and patterned OEM designs

These materials provide heat resistance, durability, fire safety, and luxury aesthetics—exactly what Middle Eastern projects require.

By partnering with a professional Chinese woven mesh manufacturer, Middle East developers and contractors gain access to high-quality, customizable, and cost-effective architectural metal fabrics.

Recommended News