-

About UsProductsCustomized SolutionProjectGalleryNews

Metal Woven Interiors Maintenance Tips for Corrosion Resistance

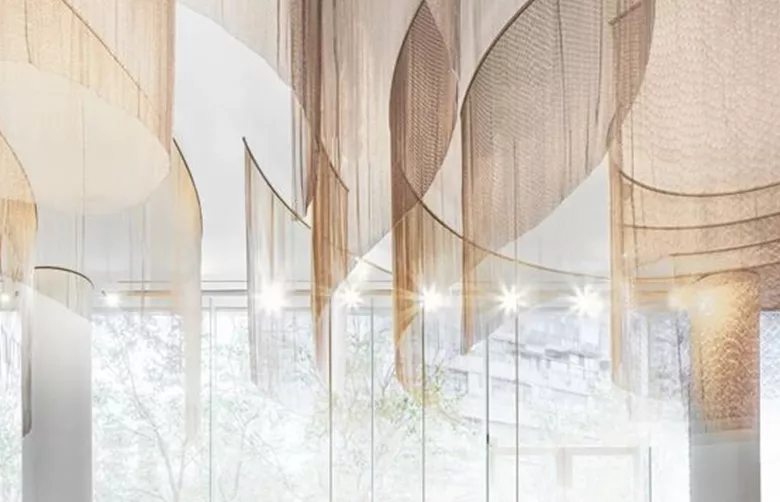

Release time: February 11, 2026Metal woven interiors are widely used in modern architecture and interior design, offering aesthetic appeal, durability, and flexibility. From decorative wall panels to ceilings, partitions, and artistic installations, metal woven fabrics enhance both residential and commercial spaces. However, exposure to moisture, dust, and environmental pollutants can lead to corrosion over time. Proper maintenance is essential to prolong the lifespan of metal woven interiors and maintain their original appearance.

This article provides a comprehensive guide on metal woven interiors maintenance for corrosion resistance, helping architects, contractors, and facility managers protect their investment.

1. Understanding Corrosion in Metal Woven Interiors

Corrosion occurs when metal surfaces react with oxygen, moisture, and chemicals in the environment. Factors that contribute to corrosion include:

Humidity and water exposure – especially in bathrooms, kitchens, or outdoor areas

Airborne pollutants – dust, salts, or industrial gases can accelerate oxidation

Cleaning chemicals – harsh detergents may damage protective coatings

Scratches or surface damage – compromise the metal’s anti-corrosion layer

Common metals used in woven interiors include stainless steel, aluminum, and coated carbon steel. Each metal has different resistance to corrosion, but all require routine maintenance for optimal performance.

2. Selecting Corrosion-Resistant Metal Woven Interiors

Before installation, choosing the right metal and finish is crucial for long-term corrosion resistance:

Stainless Steel (304 or 316) – Highly resistant to rust and ideal for humid or outdoor environments

Aluminum – Naturally resistant to corrosion and lightweight for ceilings or partitions

Galvanized Steel – Steel coated with zinc for outdoor or high-moisture applications

PVC-Coated or Powder-Coated Mesh – Adds an extra protective layer against moisture and chemicals

Selecting a high-quality metal woven interior from a reputable manufacturer ensures both durability and aesthetic performance.

3. Cleaning Tips for Metal Woven Interiors

Proper cleaning prevents corrosion caused by dirt, dust, and environmental pollutants:

Regular Dusting – Use a soft brush or microfiber cloth to remove surface dust weekly.

Gentle Washing – Use mild detergent mixed with water. Avoid abrasive cleaners or steel wool that can scratch the metal.

Rinsing – Rinse thoroughly with clean water to remove soap residues.

Drying – Always dry the metal completely with a soft cloth to prevent water spots and oxidation.

For stainless steel mesh, specialized stainless steel cleaners can help restore shine while protecting the protective oxide layer.

4. Preventive Measures Against Corrosion

In addition to regular cleaning, implementing preventive measures can significantly extend the lifespan of metal woven interiors:

Apply protective coatings – Use anti-corrosion sprays or wax coatings suitable for metal surfaces.

Control humidity – Use dehumidifiers in high-humidity areas to reduce moisture accumulation.

Avoid direct contact with corrosive materials – Keep mesh surfaces away from acids, salts, or harsh chemicals.

Inspect regularly – Check for scratches, dents, or discoloration, and address them promptly.

These preventive steps reduce the risk of oxidation, rust formation, and structural weakening.

5. Handling and Installation Tips

Proper installation and handling play a critical role in maintaining corrosion resistance:

Wear gloves to prevent oils and sweat from contacting metal surfaces.

Avoid dragging or scraping the mesh on rough surfaces.

Ensure proper ventilation in indoor installations to minimize condensation.

Use corrosion-resistant fasteners and fittings, especially for outdoor or humid areas.

Choosing a manufacturer that provides installation guidelines and after-sales support ensures that the metal woven interiors perform well over time.

6. Long-Term Maintenance Strategy

A structured maintenance strategy includes:

Monthly inspection – Look for rust spots, scratches, or loose connections.

Quarterly cleaning – Deep clean with mild detergents and water.

Annual protective coating – Apply anti-corrosion treatments if needed, especially for outdoor installations.

Professional servicing – For large-scale architectural projects, consider professional maintenance services to preserve both appearance and function.

Implementing this strategy ensures that metal woven interiors remain corrosion-free and visually appealing for decades.

7. Benefits of Proper Maintenance

Maintaining metal woven interiors not only prevents corrosion but also:

Enhances aesthetic appeal by keeping surfaces shiny and uniform

Increases structural integrity, preventing metal weakening over time

Reduces replacement costs by extending lifespan

Supports sustainable building practices by minimizing waste

This makes proper maintenance an essential part of architectural planning and facility management.

8. Conclusion

Metal woven interiors offer versatility, elegance, and durability, but corrosion can compromise their beauty and strength if left unchecked. By selecting corrosion-resistant materials, following proper cleaning routines, implementing preventive measures, and conducting regular inspections, you can ensure long-term performance of your metal woven interiors.

For global projects, sourcing metal woven interiors from an experienced Chinese manufacturer guarantees high-quality materials, customization options, and technical support to maintain corrosion resistance and visual appeal.

Recommended News