-

About UsProductsCustomized SolutionProjectGalleryNews

The Importance of Precision in Woven mesh fabric Manufacturing

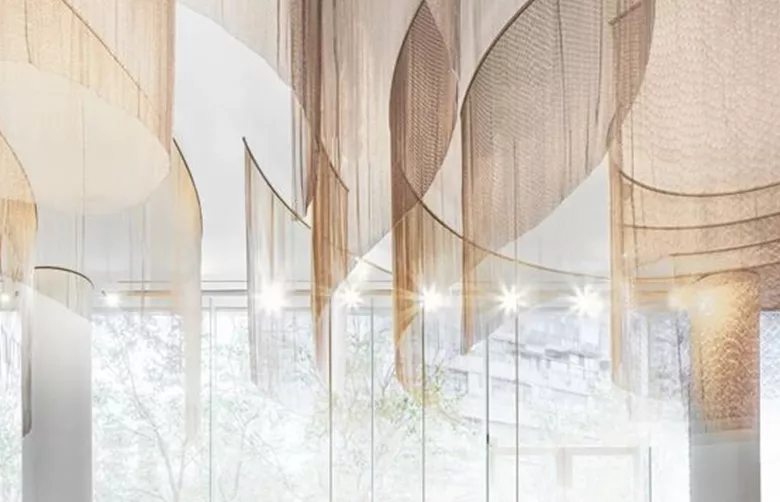

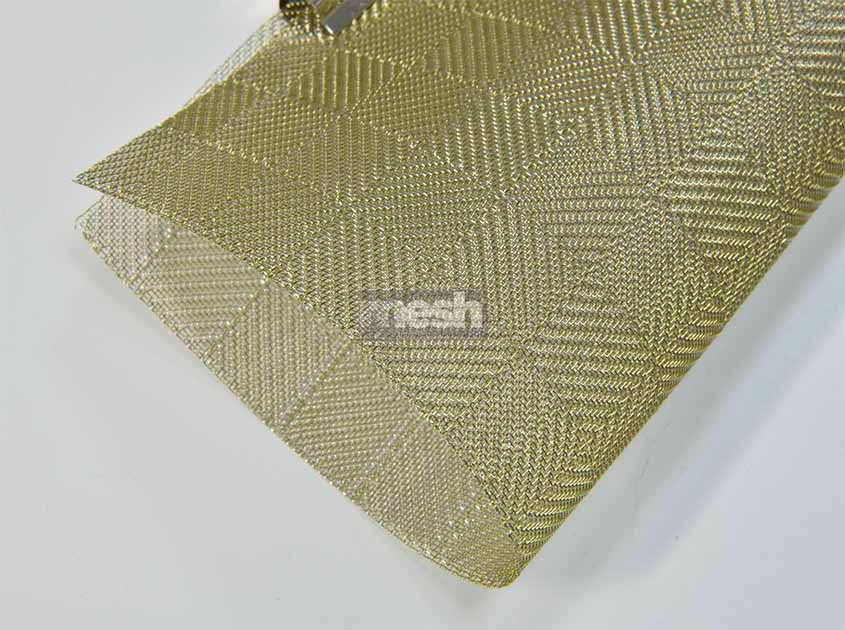

Release time: September 26, 2023Woven mesh fabric is a mesh fabric interwoven by shuttle looms and is widely used in various fields, such as protective equipment, filter materials, decorative materials, etc. This fabric has the characteristics of high strength, high durability, good breathability and aesthetics, so precision during the manufacturing process has a crucial impact on its quality and performance.

In the manufacturing process of Woven mesh fabric, the importance of accuracy is mainly reflected in the following aspects. First, precise loom settings ensure fabric quality and stability. Only when the loom parameters such as warp and weft density, shedding time, shuttle pitch, etc. are accurately adjusted, can a mesh fabric with a tight structure and even distribution be produced. Second, precise raw material selection and preparation improves fabric performance. According to different application requirements, yarns of different materials and specifications are selected and accurately pretreated to ensure that the fabric has excellent physical and chemical properties. Finally, precise process control can reduce fabric scrap rates. By precisely controlling process steps such as machine loading, harness drawing, buckling, and weaving, weaving errors and waste products can be reduced, thereby reducing production costs.

In order to improve the accuracy during the manufacturing process of Woven mesh fabric, advanced production technology and equipment can be used. For example, CNC looms can be used to automatically complete the weaving process and reduce the impact of human factors on product quality; intelligent sensors and real-time monitoring systems can be used to detect and adjust various parameters in the production process in real time, improving production efficiency and quality; The use of automated production lines and robotics technology can achieve continuous production, increase production speed and reduce labor costs.

It should be noted that the precision in the manufacturing process of Woven mesh fabric not only affects the quality and performance of the product, but also affects the production cost and market competitiveness. In order to maintain the stability of accuracy and improve product quality, it is necessary to regularly maintain and calibrate production equipment, strengthen skills training and quality awareness education for employees, and establish a complete quality control system and standardized operating procedures. At the same time, in response to different market demands and product types, manufacturing plans and process parameters need to be flexibly adjusted to achieve the best balance between accuracy and production efficiency.

Recommended News