-

About UsProductsCustomized SolutionProjectGalleryNews

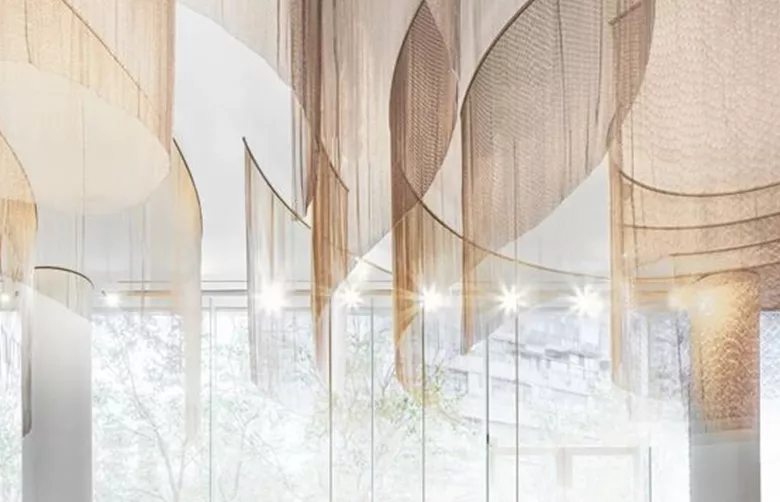

Testing and Certification of woven Metal Interiors: Quality Assurance and Standards

Release time: August 16, 2023Product Testing and Quality Assurance

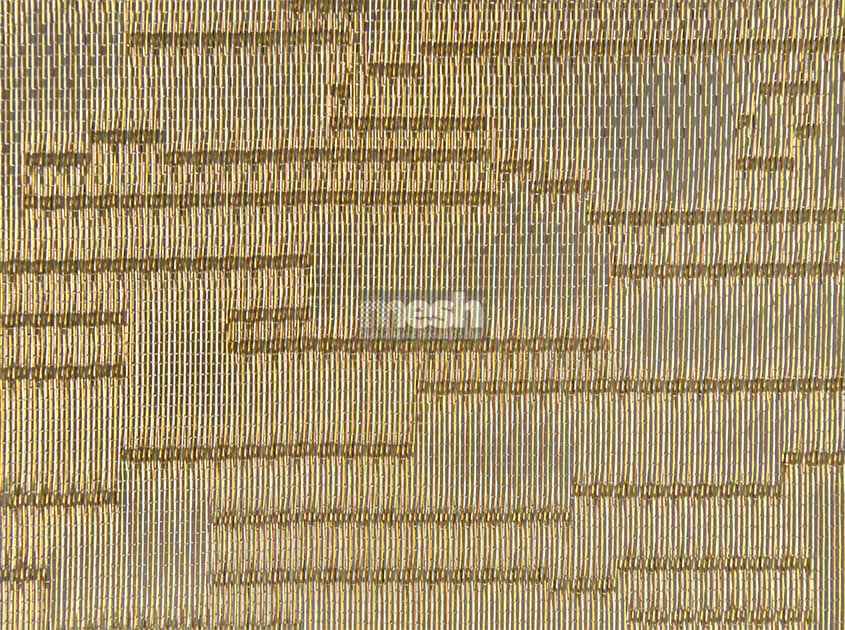

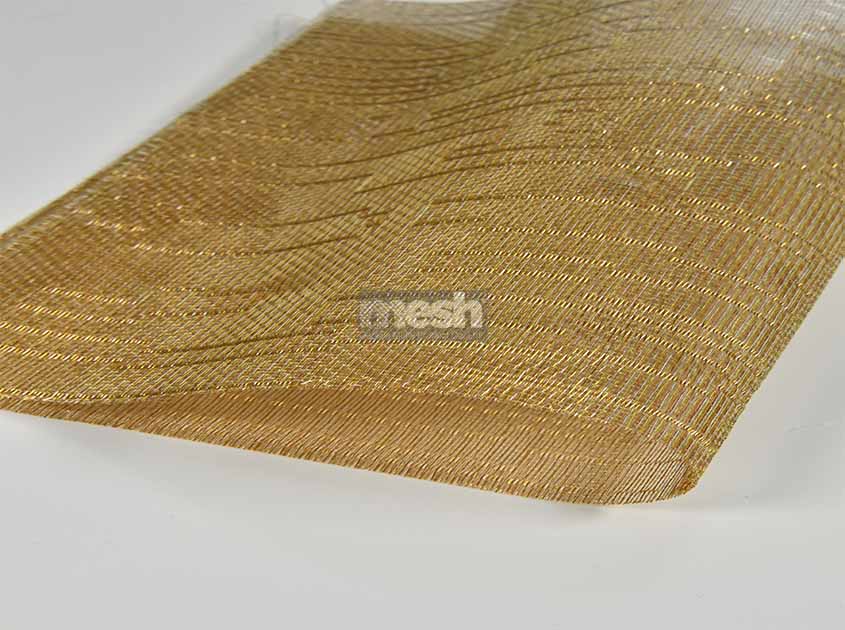

Quality assurance at woven Metal Interiors is inseparable from effective product testing. By conducting various tests such as strength test, durability test and anti-corrosion performance test, it can be ensured that the quality of woven Metal Interiors meets the standards and expectations of customers. These tests help to find potential defects and problems, and ensure the reliability and stability of the product during use.

Certification Standards and Specifications

The certification standards and specifications of woven Metal Interiors are an important basis for ensuring quality. Various countries and regions may have different certification bodies and standards, such as ISO certification, EN standards or ASTM international standards. By complying with these certification standards and specifications, we can ensure that Woven Metal Interiors meets the relevant quality and safety requirements, and provide customers with a reliable product.

Reliability and Durability Testing

The reliability and durability of woven Metal Interiors are important indicators for evaluating its quality. By conducting reliability and durability tests, such as repeated use tests, abrasion resistance tests, and corrosion resistance tests, it is possible to evaluate the performance of materials under long-term use and various environmental conditions. These tests help verify the quality and performance of woven Metal Interiors and ensure that it will stand the test of time and use.

Continuous Improvement and Tracking

Quality assurance is a continuous improvement process. During the production and supply process of woven Metal Interiors, it is necessary to establish an effective tracking and feedback mechanism, as well as monitor product quality and customer feedback. By collecting and analyzing data, formulating improvement measures, and promptly correcting any quality issues, the quality and performance of products can be continuously improved and customer needs met.

Through the description of the above four aspects, we can see the importance of quality assurance testing and standard certification of woven Metal Interiors. Through product testing, compliance with certification standards and specifications, reliability and durability testing, and continuous improvement and tracking, we can ensure that the quality of Woven Metal Interiors meets the standards and provide high-quality products to customers. This quality assurance not only enhances the trust of customers, but also ensures the reliability and durability of the products.

Recommended News