-

About UsProductsCustomized SolutionProjectGalleryNews

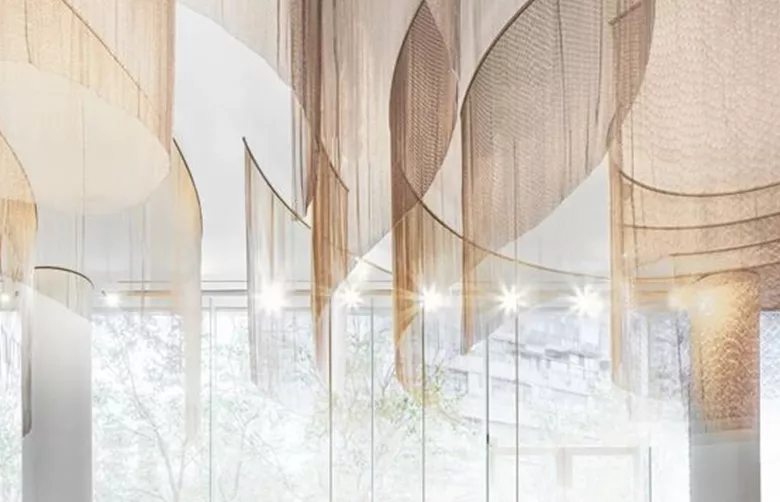

Chemical Resistance of woven Metal Interiors: Evaluating Performance and Longevity

Release time: August 09, 2023chemical properties

The chemical resistance of a woven Metal Interiors is often determined by its material and surface treatment. Different metal materials have different chemical properties and corrosion resistance. For example, stainless steel has good corrosion resistance and chemical stability, while aluminum is sensitive to certain chemicals. In addition, the surface treatment of woven Metal Interiors can also affect its chemical properties, such as anodizing, plating and coating. These treatments improve the chemical and corrosion resistance of woven Metal Interiors.

Evaluate performance

The chemical resistance performance and lifetime evaluation of woven Metal Interiors can be carried out through experiments and simulations. Experimental methods often include exposure testing and immersion testing to simulate how woven Metal Interiors will perform in different chemical environments. Simulation methods can be performed using computer simulation software to predict the lifetime and performance of woven Metal Interiors in different chemical environments. These evaluation methods can help designers choose the most suitable metal material and surface treatment to meet different application requirements.

life assessment

The life evaluation of woven Metal Interiors is to evaluate its service life and reliability under different chemical environments. Lifetime assessments can be performed through experiments and simulations. Experimental methods often include exposure testing and immersion testing to simulate the service life of woven Metal Interiors in different chemical environments. Simulation methods can be performed using computer simulation software to predict the lifetime and reliability performance of woven Metal Interiors in different chemical environments. These evaluation methods can help designers choose the most suitable metal material and surface treatment to meet different application requirements.

maintain

woven Metal Interiors require regular maintenance during use to extend their life and maintain their performance. Maintenance includes cleaning and maintenance etc. Proper cleaners and cleaning tools should be used to avoid damage to the woven Metal Interiors. In addition, the surface and structure of the woven Metal Interiors should be inspected regularly, and necessary repairs and replacements should be carried out.

To sum up, the chemical resistance and life evaluation of woven Metal Interiors are the key factors for their application in different environments and applications. Evaluation through experimental and simulation methods can help designers choose the most suitable woven Metal Interiors and surface treatment, and extend the service life of woven Metal Interiors. During use, the woven Metal Interiors should also be maintained regularly to prolong its life and maintain its performance.

Recommended News