-

About UsProductsCustomized SolutionProjectGalleryNews

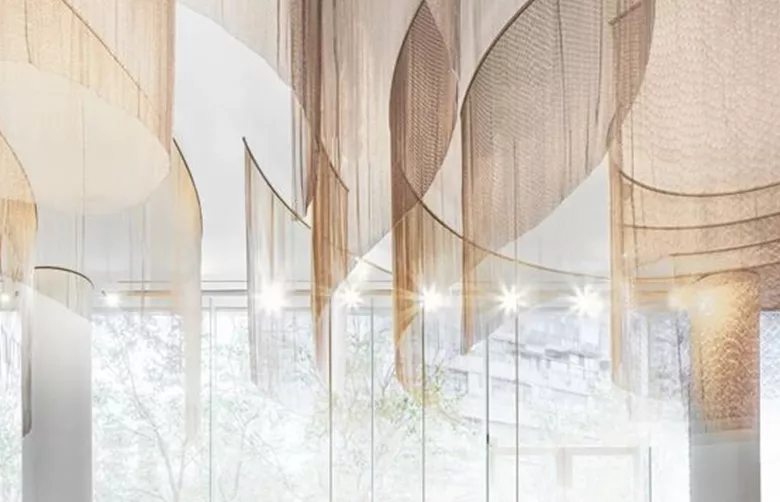

Advances in Textile woven mesh Technology: Pushing the Boundaries of Innovation

Release time: September 07, 2023Textile woven mesh technology continues to push forward through material innovation. Traditional textile webs mainly use natural fibers or synthetic fibers such as cotton, polyester and nylon. However, with the development of technology, the introduction of new fiber materials has brought new possibilities to Textile woven mesh. For example, high-performance fiber materials, such as carbon fiber and aramid fiber, have excellent strength and durability, enabling textile webs to withstand more stringent environmental requirements. In addition, the application of functional fiber materials, such as waterproof, fireproof and antibacterial fibers, further broadens the application range of Textile woven mesh.

Structural design:

Textile woven mesh technology has also made significant progress in structural design. Traditional textile mesh structures are usually planar with a fixed pore size and linear density. However, the current Textile woven mesh structure has become more diverse and complex. For example, by changing the weave of the threads, the shape and size of the holes, different functions and performances can be achieved. The introduction of new textile mesh structures, such as three-dimensional woven mesh and double-sided mesh structure, provides higher strength, better breathability and more decorative options. These innovative structural designs have promoted the further development of Textile woven mesh technology.

Functional application:

The progress of Textile woven mesh technology is also reflected in functional applications. In addition to providing basic isolation and screening functions, textile meshes can now also fulfill various additional functions. For example, some Textile woven meshes are UV-resistant, anti-pollution, and anti-dust mite, making them widely used in outdoor shading, air filtration, and household items. In addition, the textile net can also be embedded with sensors and smart technologies to realize functions such as intelligent monitoring, data collection and remote control, bringing innovative solutions to the fields of industry, medical treatment and smart home.

Sustainability:

The advancement of Textile woven mesh technology is also closely related to sustainable development. As concerns over environmental impact increase, textile web technology is seeking more environmentally friendly and sustainable solutions. For example, using renewable materials, recycled fibers and biodegradable materials to manufacture Textile woven mesh can reduce resource consumption and environmental pollution. In addition, the design and production process of textile webs are increasingly focusing on energy efficiency and waste reduction in order to achieve sustainable development goals.

To sum up, the progress of Textile woven mesh technology is reflected in material innovation, structural design, functional application and sustainable development. These advances have promoted the development of Textile woven mesh technology, which has wider applications and higher performance requirements in various fields.

Recommended News